SID Business Conference 講演概要 (MicroLED編)

冒頭部和訳

SID Business Conferenceの2日目には「MicroLED ディスプレイの商業化」と題したセッションが開催され、Counterpoint Research、Aledia、Smartkem、InZiv、Pixel-Floの5社が講演を行った。本稿ではこのセッションのみを取り上げるが、カンファレンス初日には、Tianma (基調講演) とVueReal (自動車セッション) の講演でもMicroLED技術について議論が行われた。

筆者の講演では、XRアプリケーションとMicroLEDのターゲット市場に焦点を当てた。まず、VRにおける課題の一部を詳細に説明し、ヘッドセット出荷数が3年連続で減少している点を指摘した。ARスマートグラスも2024年に出荷数が減少したが、主要OEMの製品発売およびAIとARの統合に向けた取り組みにより、2025年には前年比30%増と急成長が見込まれている。ただし、ディスプレイを搭載しないスマートグラス (例:Ray-Ban Metaスマートグラス) が現在、はるかに高い成長率を示している。FPD業界にとっての課題は、ユーザーを音声機能のみのグラスからARグラスへ移行するよう促すことである。

SID Business Conference: MicroLED Session Overview

On the second day of the SID Business Conference, a session on ‘MicroLED Display Commercialization’ featured five talks from Counterpoint, Aledia, Smartkem, InZiv and Pixel-Flo. While this report will only focus on this session, it should be noted that MicroLED technology was also discussed by Tianma (keynote session) and VueReal (automotive session) on Day 1 of the conference.

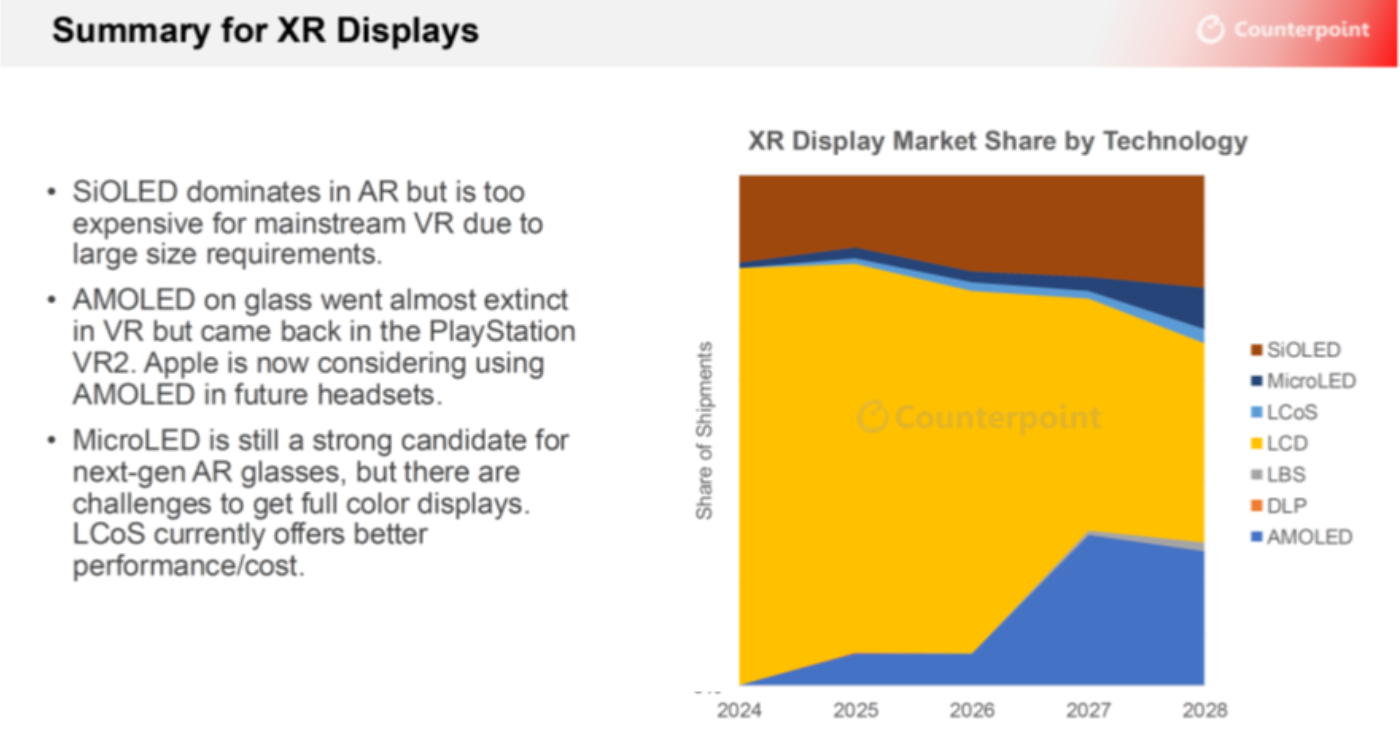

My presentation focused on XR applications and the addressable market for MicroLED. I started by detailing some of the challenges in VR, with headset shipments in decline for three consecutive years. Shipments of AR smart glasses also declined in 2024 but are expected to soar 30% YoY in 2025, driven by product launches from major OEMs and efforts to combine AI with AR. However, smart glasses without display, such as the Ray-Ban Meta smart glasses, are currently growing at a much higher rate. For the display industry, the challenge will be to convince users to transition from audio-only glasses to AR glasses.

OLED on Silicon (SiOLED) currently has the largest share in AR due to the prevalence of Smart Viewers from Chinese brands such as XREAL, RayNeo, Rokid and Viture. However, we expect more lightweight smart glasses to be based on MicroLED and LCoS. While Meta’s Orion smart glasses are not ready to be commercialized yet, there are already several other brands that have launched lightweight glasses with a monochrome MicroLED display. This category is still a niche currently, with shipments expected to reach only 120,000 units in 2025. MicroLED remains a strong candidate for future AR glasses, but the technology needs to progress and enable full-color displays on single panels.

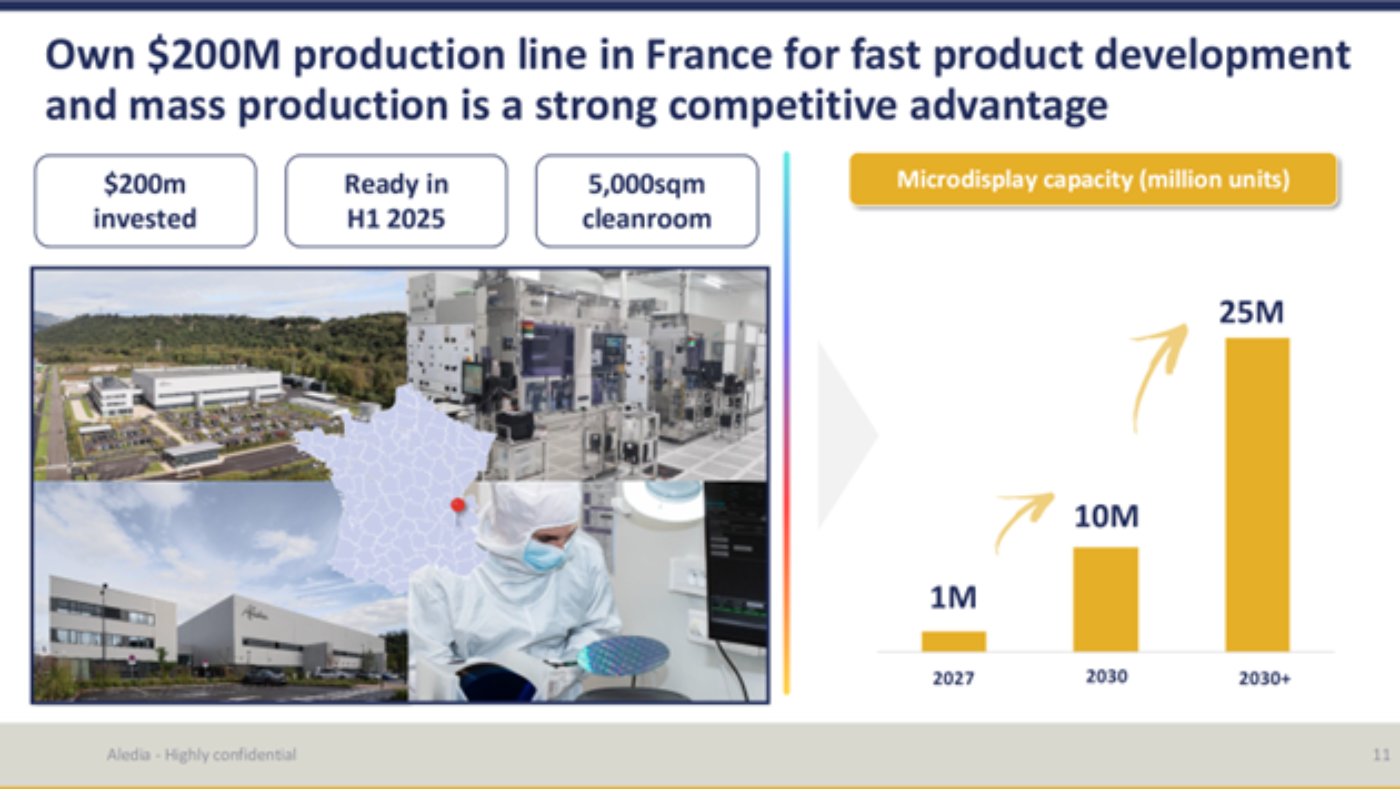

Pierre Laboisse, Aledia

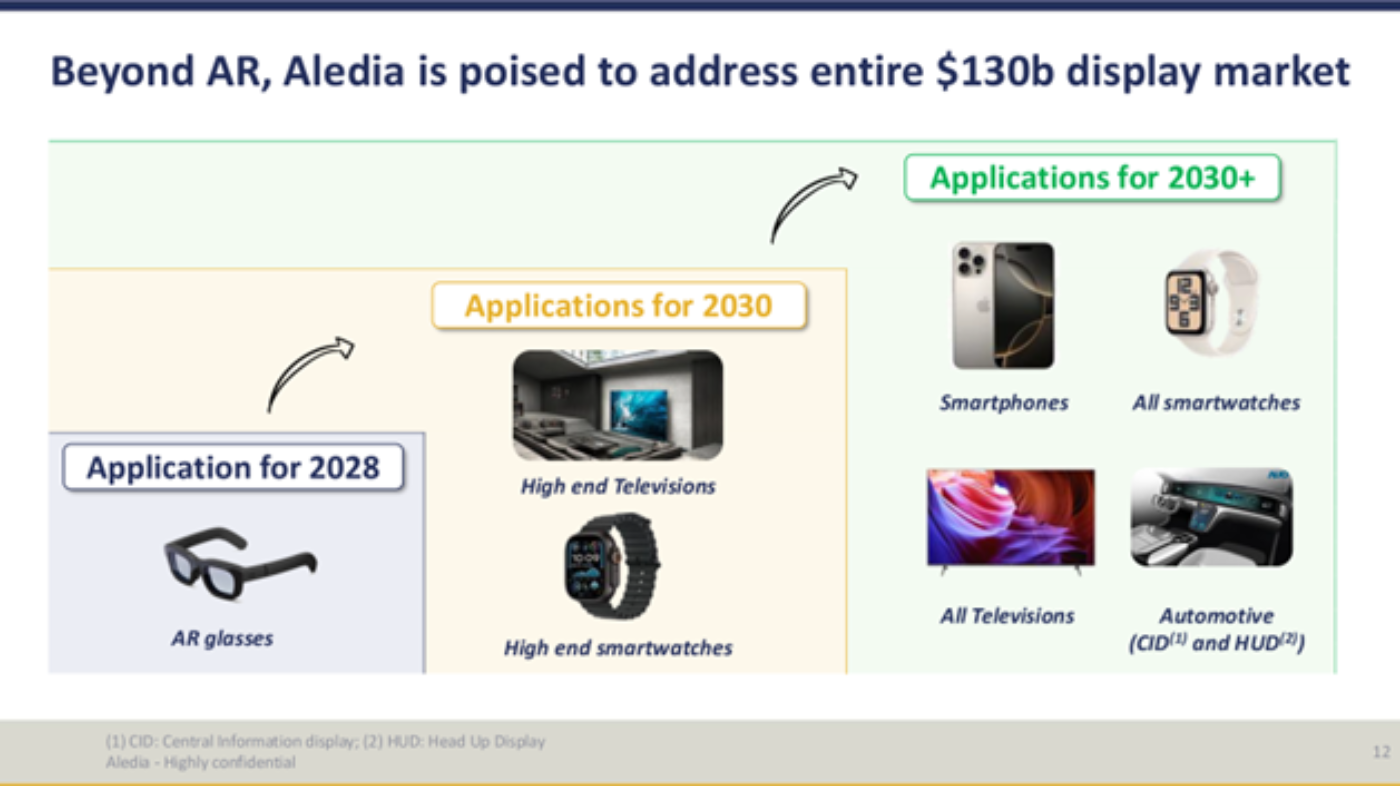

Aledia has built a $200-million fab in France to make MicroLED on 8” wafers, using its nanowire GaN-on-Silicon technology. The company plans to ramp up the capacity from 1 million microdisplays in 2027 to 10 million by 2030. The nanowire structure enables two things – RGB full color on a single monolithic display and highly directional emission to maximize coupling efficiency into waveguide optics. Aledia believes the 8” production line will help achieve a price of $50-$75 for a high-end RGB display.

Aledia is not just targeting AR glasses. During Display Week, the company launched its Flexi Nova platform for designing and producing blue MicroLED chips of any size down to 3.5 μm, while preserving an EQE of 37%. This technology is aimed at MicroLED displays that are manufactured by mass transfer of chips, such as smartwatches and TVs. Since it is optimized for blue emission only, color conversion will be required for green and red subpixels.

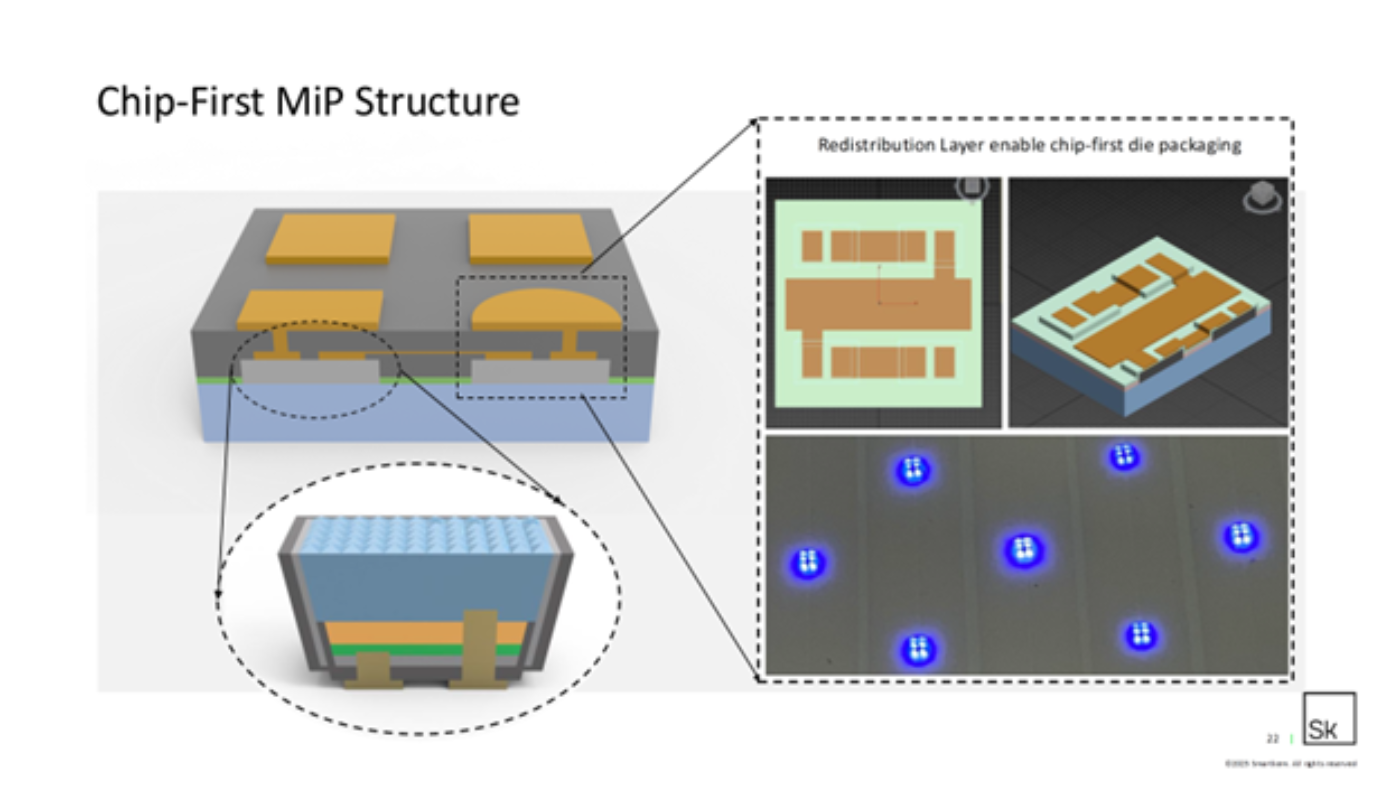

Ian Jenks, Smartkem

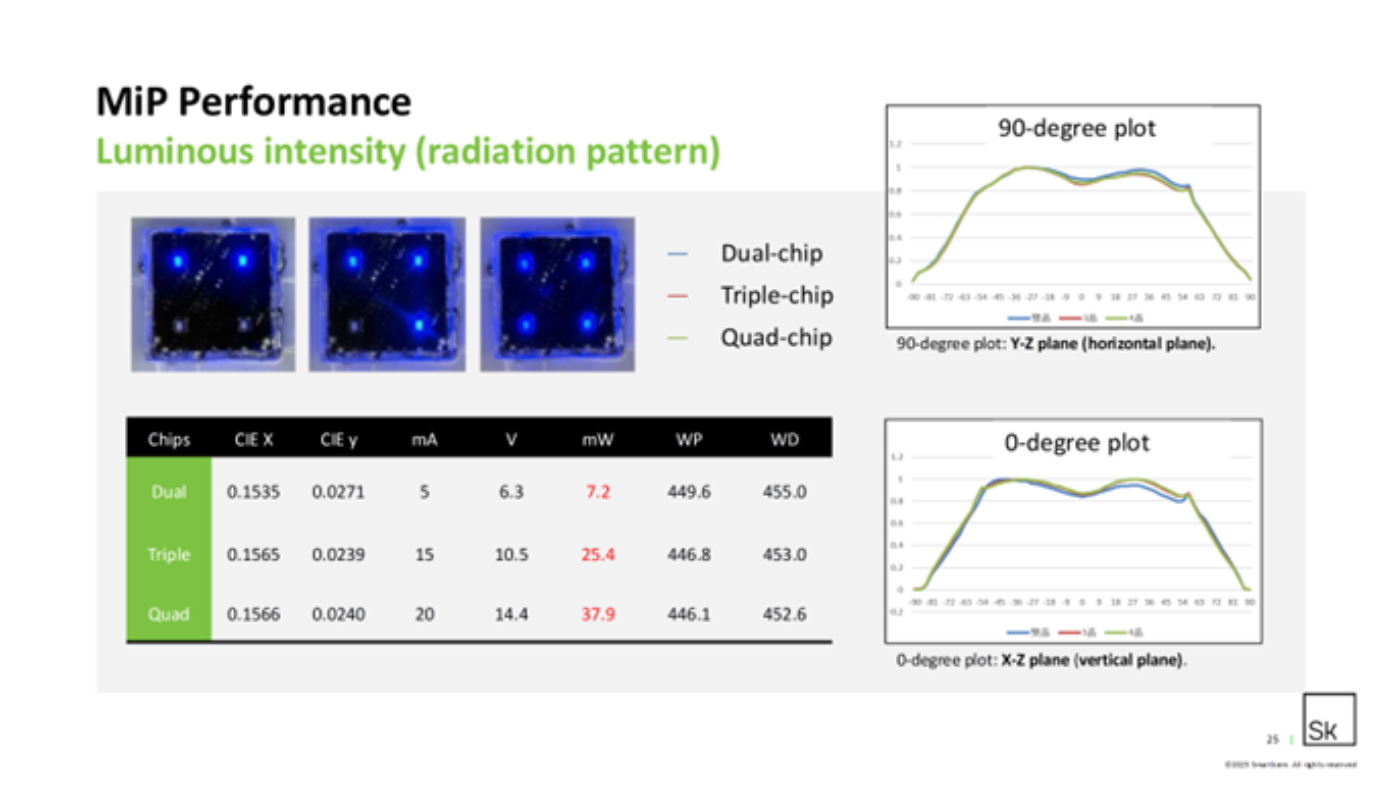

Smartkem previously introduced a MicroLED display architecture based on a “chip-first approach” and the fabrication of an organic TFT backplane directly on top of MicroLED chips. Smartkem is still developing this approach in collaboration with ITRI of Taiwan. By using the same dielectric planarization layer and redistribution layer, Smartkem can also make a MicroLED backlight for high-performance LCD. It uses its new MiP4 package that consists of four MicroLED chips (85 μm × 85 μm) connected in series to form a glass-based high-voltage backlight component.

While on stage, Ian Jenks demonstrated a 12.3” backlight panel where each of the 532 zones is controlled with a single MiP4 package. Smartkem believes this is an opportunity to commercialize MicroLED by offering an alternative to existing MiniLED chips. Future implementations could integrate on-chip quantum dot color conversion to make RGB packages.

While on stage, Ian Jenks demonstrated a 12.3” backlight panel where each of the 532 zones is controlled with a single MiP4 package. Smartkem believes this is an opportunity to commercialize MicroLED by offering an alternative to existing MiniLED chips. Future implementations could integrate on-chip quantum dot color conversion to make RGB packages.

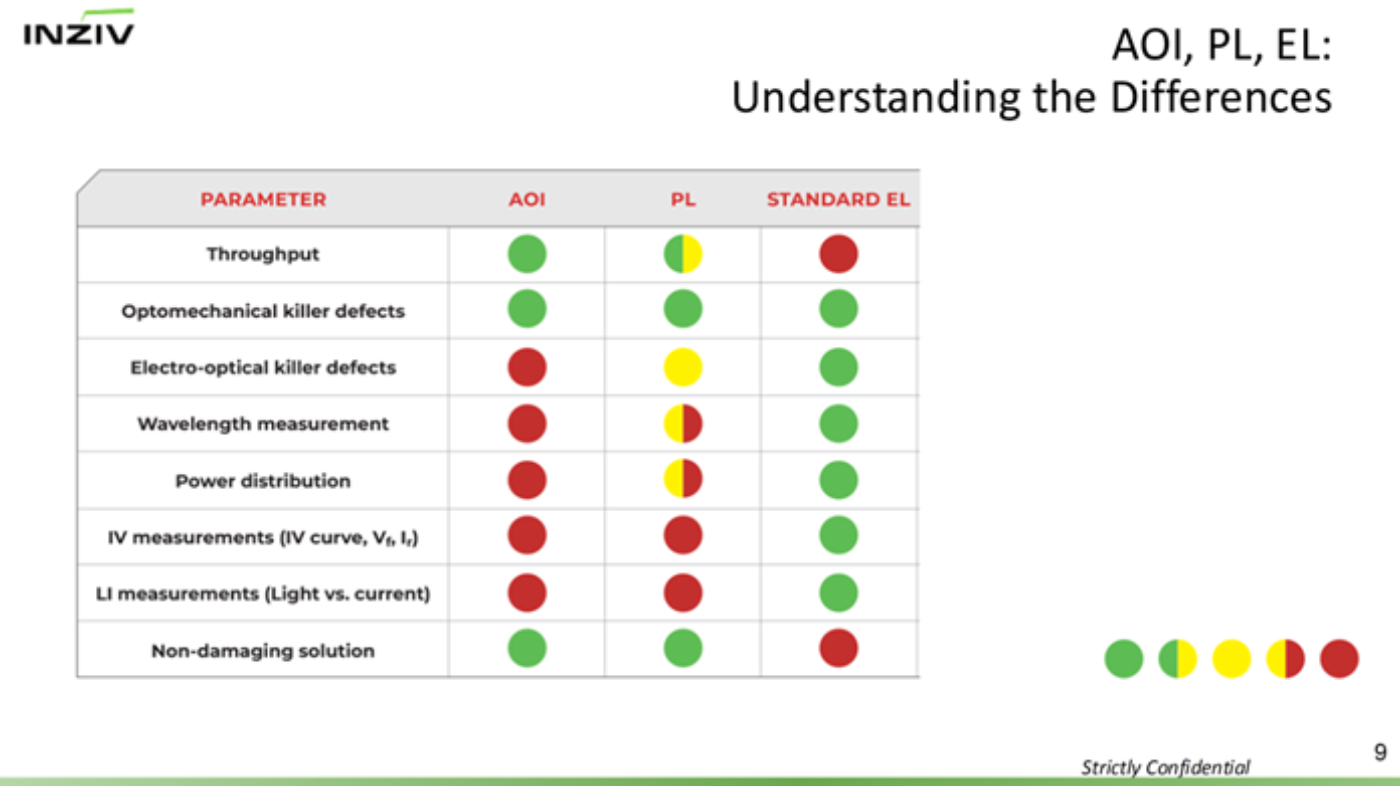

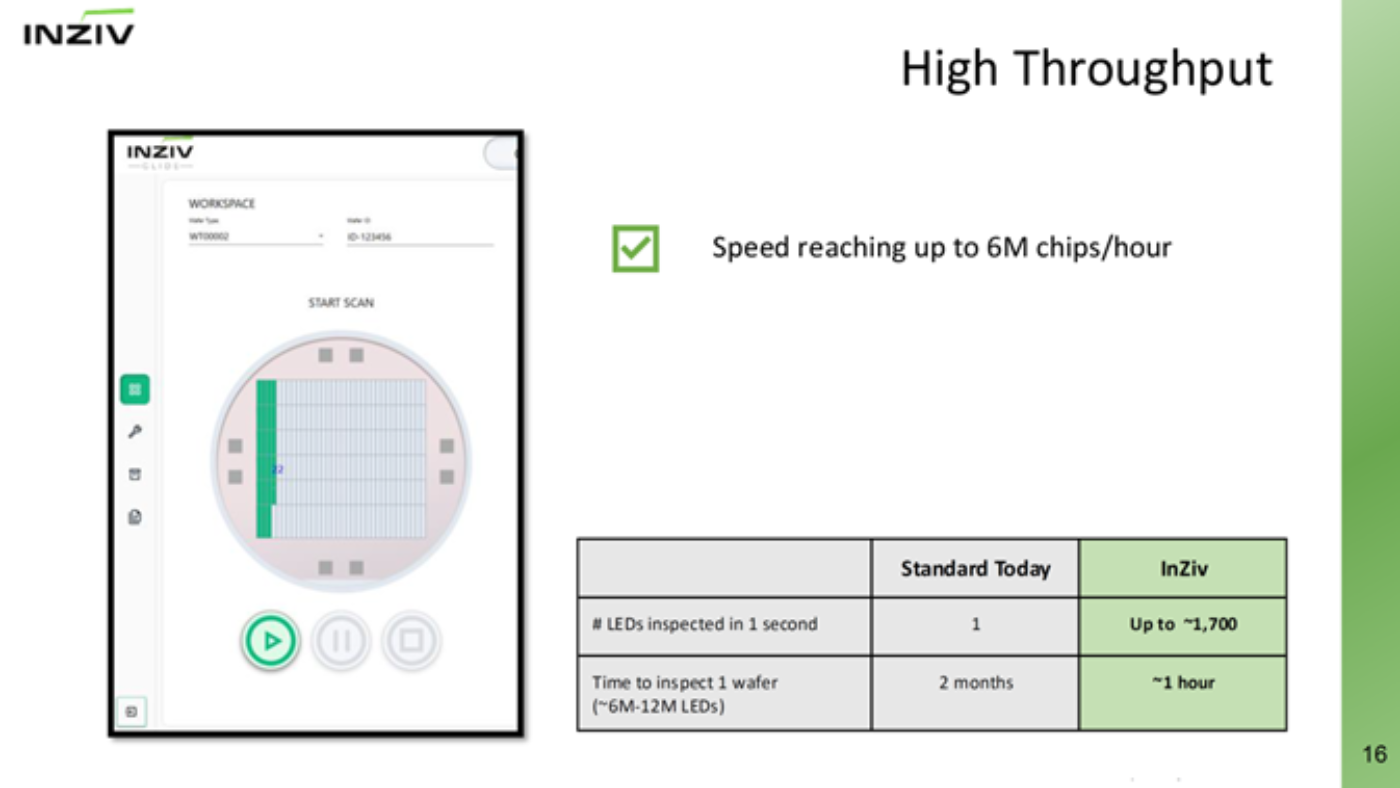

David Lewis, InZiv

InZiv has developed an inspection tool that can test the electroluminescence (EL) of all MicroLED chips on a wafer at high throughput. An early-stage inspection provides an opportunity to catch defective chips before mass transfer, thus increasing yields. For MicroLED displays, EL testing is far more indicative of real-world performance than Automated Optical Inspection (AOI) or photoluminescence (PL) testing.

InZiv developed its R-EL Glide tool because standard EL probes are too slow for the production environment, only averaging one LED per second. Moreover, a standard probe can scratch the contact pad of the chip, resulting in irreversible damage. The R-EL Glide uses patented contact probe technology that enables damage-proof testing. It is designed for wafers up to 12” in size and the software gives a clear go/no-go diagnostic to identify which chip to discard.

Simon Jones, Pixel-Flo

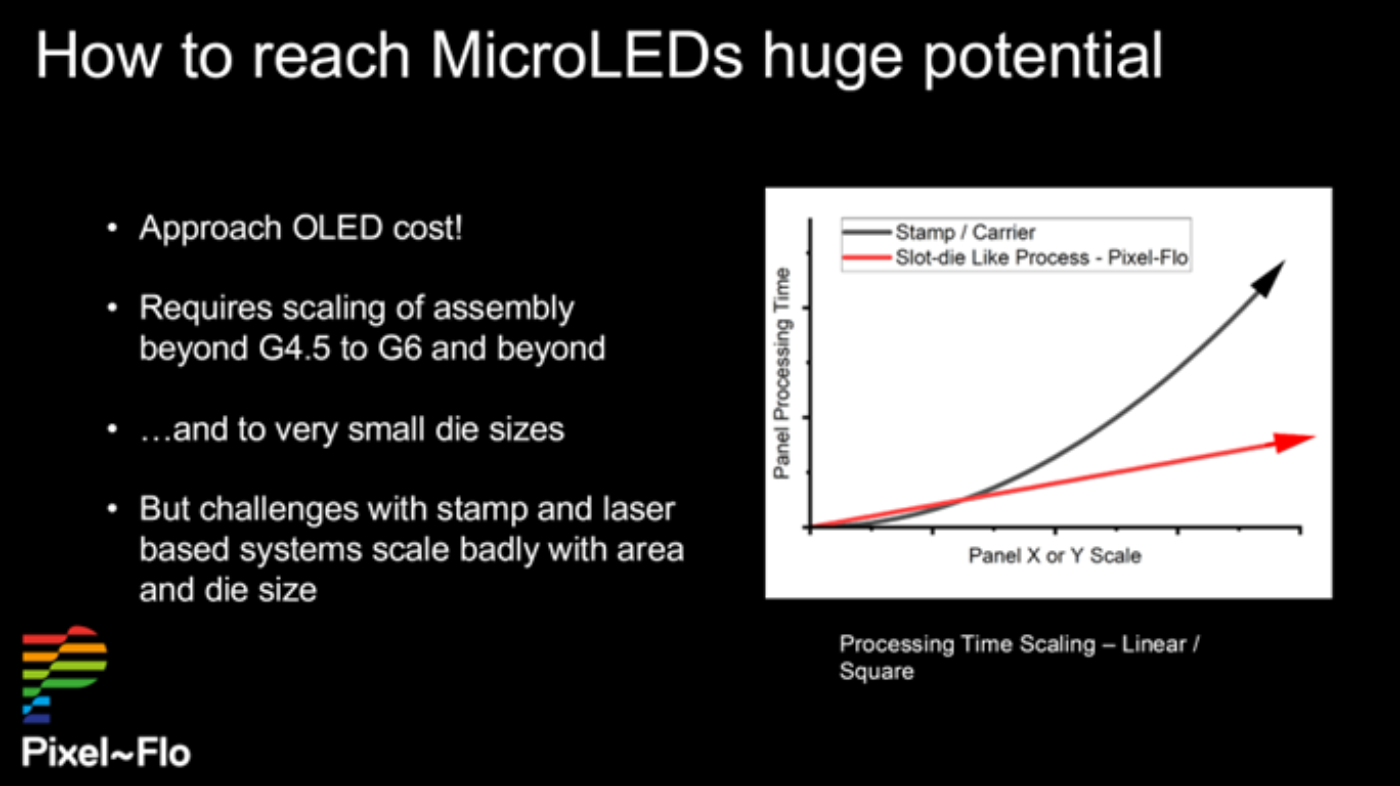

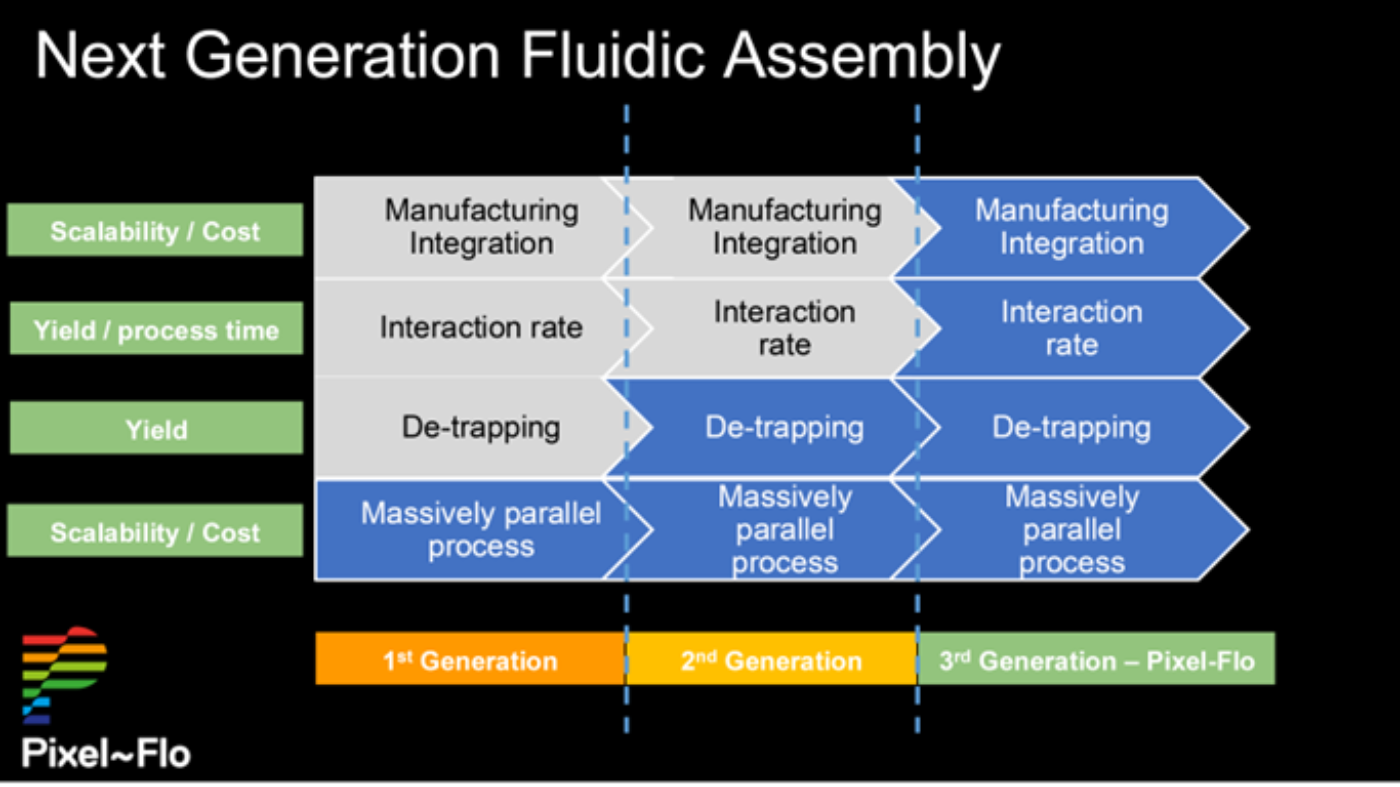

Pixel-Flo is a startup that came out of stealth mode for Display Week. The company is working on a new mass transfer technology based on slot-die coating. This means that the tool is defined by the lateral dimension of the substrate instead of the total area. As a result, it should be simple to scale to G6 substrates and beyond.

Pixel-Flo uses a fluidic assembly approach, whereby the MicroLED chips are suspended in solution. During slot-die coating, evaporation of the solvent greatly increases the concentration of MicroLED chips, which in turn increases the chances of trapping the chips on the substrate. Pixel-Flo did not reveal the trap mechanism but brought a sample to demonstrate MicroLED chips arranged in an array after transfer. The company is VC-backed and plans to raise seed funding by next year.