SID Business Conference 講演概要 (自動車編)

冒頭部和訳

SID Business Conferenceの自動車セッションでは、貿易政策からエレクトロニクスアーキテクチャに至るまで、業界が急速に変化している状況と、関連するディスプレイ技術の動向に焦点が当てられた。筆者は、自動車メーカーに圧力をかけている主要動向と、センター・インフォメーション・ディスプレイ (CID) およびデジタル・インフォメーション・クラスタ (DIC) に関する動向の概要を中心に講演を行った。

SID Business Conference Automotive Session Overview

At the SID Business Conference, the automotive session focused on how the industry is rapidly changing, from trade policy to electronics architectures, and related display technology trends. My presentation focused on key trends putting pressure on automakers and an overview of trends related to center information displays (CIDs) and digital instrument clusters (DICs).

The presentation described the effect of the current US government’s tariffs on automotive imports and on global vehicle sales. Counterpoint’s EV service has created three separate forecast scenarios for 2025, where global sales could be between 80.1 and 81.9 million units, depending on trade negotiations between the US and other countries and whether the administration changes its automotive industry tariff policy.

In addition, my presentation focused on powertrain trends where the global share of internal combustion engine (ICE) vehicle sales shrank from 74.5% in Q1 2023 to 63.9% in Q4 2024. The share of electrified powertrains in total, including hybrid electric vehicles, plug-in hybrid electric vehicles, fuel cell electric vehicles and battery electric vehicles, increased from 25.5% in Q1 2023 to 36.1% in Q4 2024.

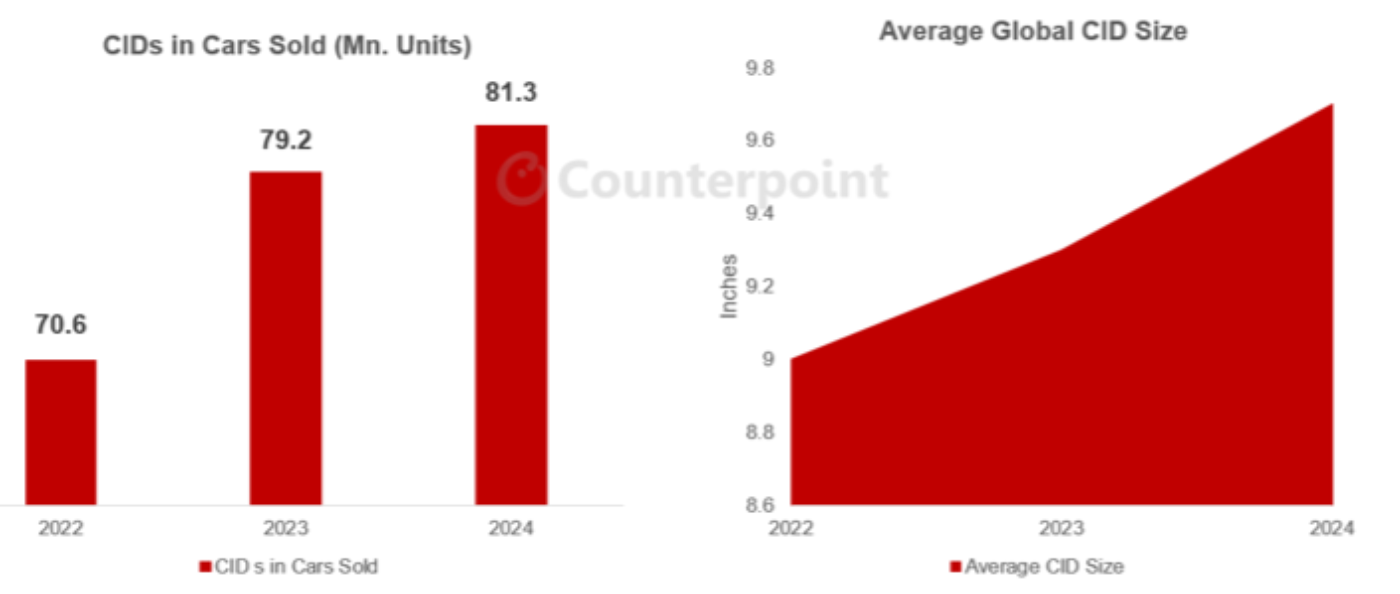

For display trends, examples I highlighted included the facts that CID penetration in car sales was closing in on 100%, and that the average CID size had increased from 9 inches in 2022 to 9.7 inches in 2024. In addition, the number of cars with digital instrument clusters had increased to 78.5% of cars sold in Q4 2024.

CID Shipments and Average CID Size, 2022-2024

For the presentations that followed, Yuichi Motohashi, Senior Manager/Deputy Director End Markets at GlobalFoundries, focused on how automotive displays are changing, from current automotive display requirements to the increasing number and size of displays in cars. For example, for display requirements, as compared with consumer displays, typical automotive requirements include brightness (Nits) of 800 to 1,000, as opposed to 250 to 400 for consumer displays. Product lifetime requirements are 5 to 10 years for automotive, rather than 1 to 2 years for consumer displays. Operating temperature requirements are -30 to 85°C (up to 105°C in some cases). Further, suppliers need to meet IATF/ISO 16949 and ISO 26262 (for functional safety) requirements.

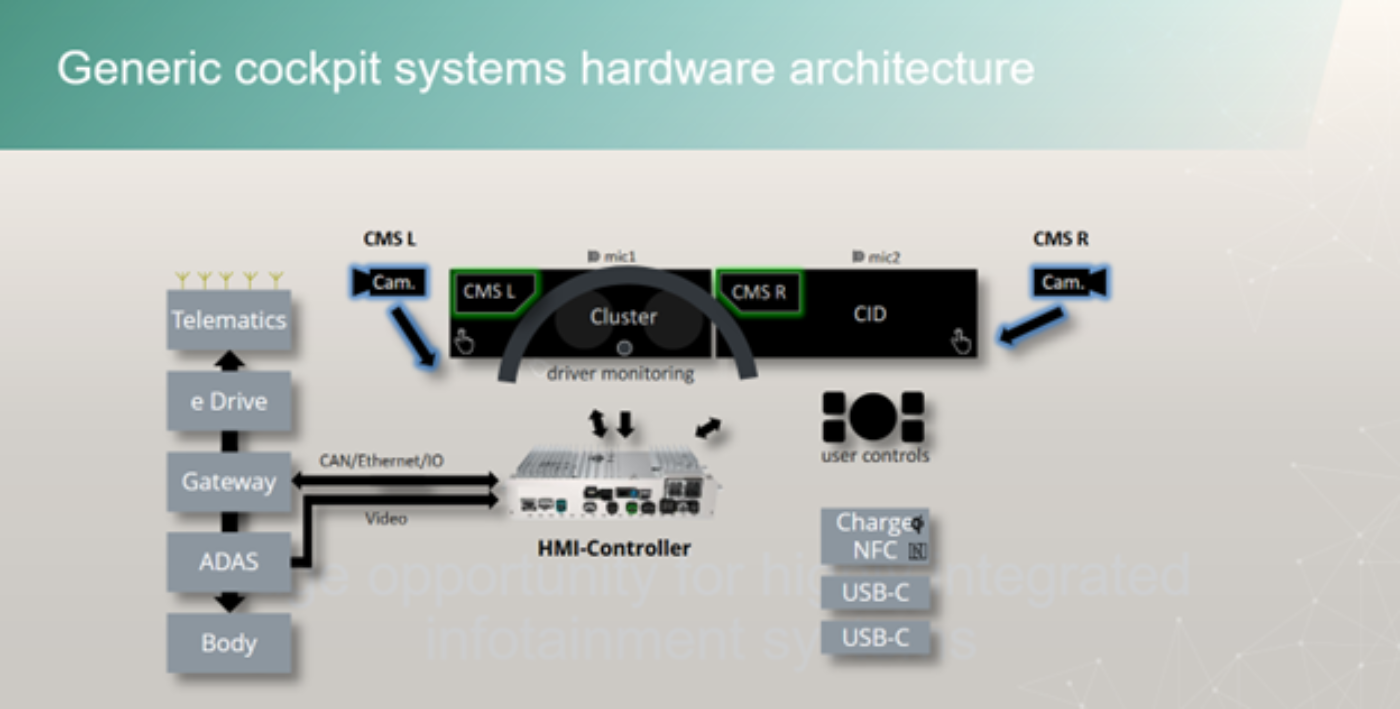

In addition, the presentation showed how display configurations have multiplied in cars. These include small, individual displays, multiple display panels under a single piece of cover glass (for example, a DIC panel and a CID panel side by side under cover glass), and a single, large panel under cover glass. These changes in configuration are occurring as the auto industry consolidates infotainment, instrument cluster and other functions in one electronic control unit (ECU), such as a cockpit domain controller or cockpit high-performance compute ECU.

For small-to-medium displays, they have traditionally featured a touch-and-display driver integration (TDDI) chip with an integrated timing controller (TCON) that processes the display control signal and LED control signal to control local dimming. For large, ultra-wide high-resolution displays, the TCON and large touch driver integration (LTDI) are separate since multiple LTDIs are necessary to drive them. From a semiconductor perspective, next-generation displays require high-bandwidth interfaces, non-uniformity compensation (enabled by high-density SRAM) for local dimming, and high-precision voltage output for the display panel source driver. GlobalFoundries’ Motohashi went on to describe the company’s products and roadmap for its display semiconductor products. This includes its 40LP-HV-Gen2 Platform, targeting LCD displays. The company plans to provide its first silicon-based PDK in Q3 2025 and the PDK v1.0 in Q4 2026. Its automotive display roadmap currently goes down to 22nm.

The next presentation was by Dr Siegfried Dirr, Head of Strategic Business Development at Elektrobit. It focused on the cost pressures that automakers are under due to a mix of inefficient capital spending, including high software costs and failed efforts to develop next-generation in-vehicle software architectures. In addition, in the market, there are only so many people on Earth who have enough income to afford an electric vehicle that costs more than $20,000 per year. Dirr’s presentation then moved to describe, at a high level, the typical next-generation digital cockpit architecture, as shown in the following diagram.

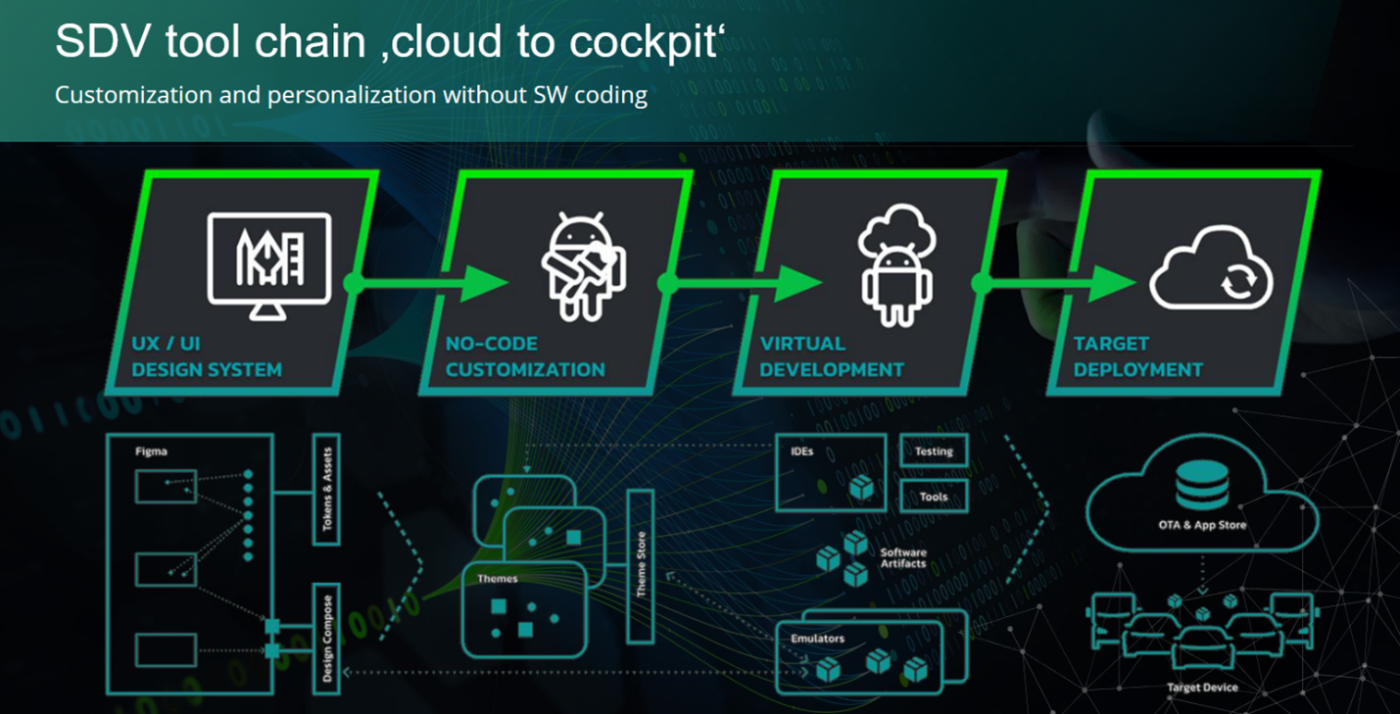

For display panel suppliers, Dirr identified the market opportunity that vertical integration offers. An example of this for display panel suppliers is to move “up the stack” and provide the display module as well as some related software. Due to the cost pressures on automotive suppliers in general, Dirr suggested that a collaborative business model can be more profitable by providing fully qualified, scalable solutions, including software and hardware stacks for automakers. He described a “car-to-cloud” toolchain that would enable companies without as much software engineering expertise to offer software-based customization options to Tier 1 suppliers and OEMs.

The final presentation, by Dr Reza Chaji, Founder and CEO of VueReal Inc., focused on MicroLED applications and the path to commercializing it for automotive use cases. Example use cases include interior displays such as CIDs, DICs and head-up displays, exterior vehicle displays, and automotive lighting.

Chaji provided an overview of the company, noting its growth to 70 employees. He proposed that the company’s MicroSolid Printing, cartridge-based manufacturing method could be adapted to produce yields large enough to work for lower-volume automakers, enabling the MicroLED ecosystem to scale up.

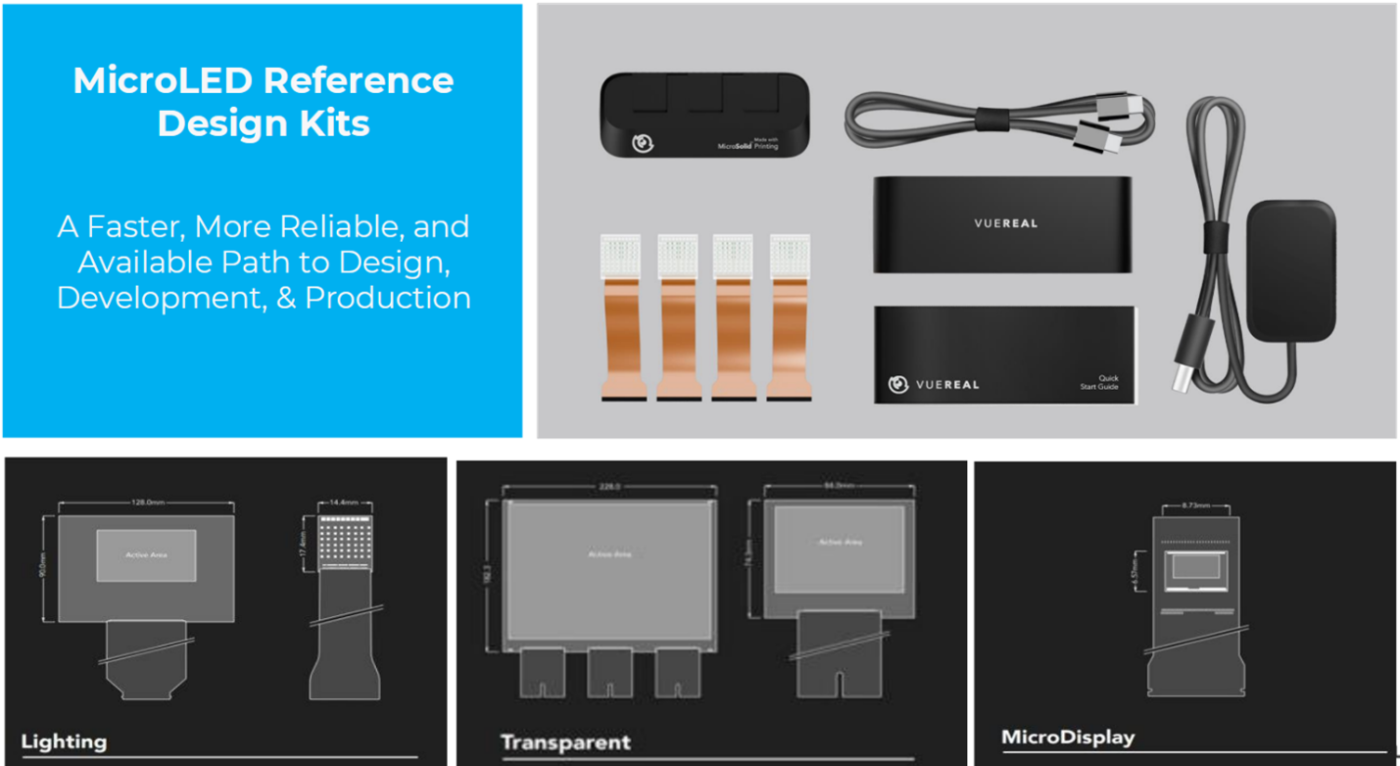

Although Chaji has been promoting VueReal’s MicroSolid Printing method for several years, he noted the company now provides MicroLED reference design kits (RDKs) to enable companies to accelerate the process of using VueReal’s method.

In addition to the new RDKs, Chaji discussed automakers’ requirements for displays, including ease of manufacturing, low cost of ownership, simplified integration, advanced functions without complexity, supply chain resiliency, that they enable designs, that they don’t compete for space, and low-cost customizability.

Chaji then focused on the benefits of MicroLED displays for automotive applications, including enhanced transparency, no need for thermal management and advanced phosphor integration. Regarding transparency, Chaji said VueReal has improved transparency by a factor of two by modifying the backplane layers using a new pixel and driving scheme and new layer stacking approach.

Moving beyond the benefits of MicroLED displays, he cited several automotive applications, including exterior vehicle displays (for example, a display on a robotaxi’s exterior for communicating with pedestrians), smart lighting and window displays (turning interior windows into displays).